Process Improvement

Feels Like Busy Work Sometimes? You're Not Alone.

Artificial Intelligence. Automation. IoT. Big Data. 5G. Virtualization. Cloud. And the list goes on.

There is no shortage of new acronyms and buzzwords that we are forced to keep up with. While Operators are pushing the cutting edge, they have the challenge of keeping up with the tremendous growth and bandwidth needs of their subscribers.

This challenge means that INTERNALLY they need to ensure that they are functioning with the utmost Operational Efficiency. Easier said than done. How many of us come into work thinking, "Today I'm going to get through my To-Do List", only to get distracted with meetings, urgent requests, and other distractions that come along? This, by our definition, is what we refer to as Busy Work and it's getting in the way of progress. In fact, when speaking to our customers we always seem to come come across 3 Major Concerns of "Busy Work". Please see below:

Challenge #1: Takes Too Long

Things just take too long. Whether it's a Structural Design, Internal Approval, or getting a Site On Air.

Challenge #2: Distractions

More work gets in the way of our to-do list. This forces us to do more with less (time).

Challenge #3: Uncommon Goals

When different department have different goals it can put progress to a halt.

Our Approach

To some extent everyone knows or is implementing some sort of Process Improvement. We have no choice. But the reality is that most organizations tend to strive for Efficiency over Effectiveness. This often results in more band-aid solutions because too much focus is on solving a smaller task or improving a single job, i.e., losing site of the overall objectives.

Our Approach is simple. We simply start off by having conversations. But we employ use of Lean Six Sigma tools and techniques to uncover solutions that you'd never consider. While we stay true to the Six Sigma Frameworks of DMAIC and DMADV, below is a more 'digestible version' of what we're doing.

Understanding Your Business (Define)

Our goal is to understand your business better than you! What that simply means is that our trained Lean Six Sigma Engineers come into the market to spend time with all levels of the organization to understand:

1. The Roles and Responsibilities of the employees

2. The Processes and Tools being used

3. The Business Objectives of each Management Layer

4. The Challenges that each employee and group seem to have

5. The Success Criteria that each group and employee measure themselves by

With this information we're able to move on to the next phase.

Documenting your Current State & Gap Analysis (Measure & Analyze)

During this phase we're able to document your processes and identify the gaps or problems that are prevalent. The importance of doing this is to have a visual that will allow all teams to chime in and more importantly buy-in. But the main goal is to identify Gaps or what is known in the Lean World as WASTES. Examples of WASTES in the RAN world can be:

1. Waiting Time

2. Re-Work

3. Inventory (Bill of Materials, or Jobs left in queues)

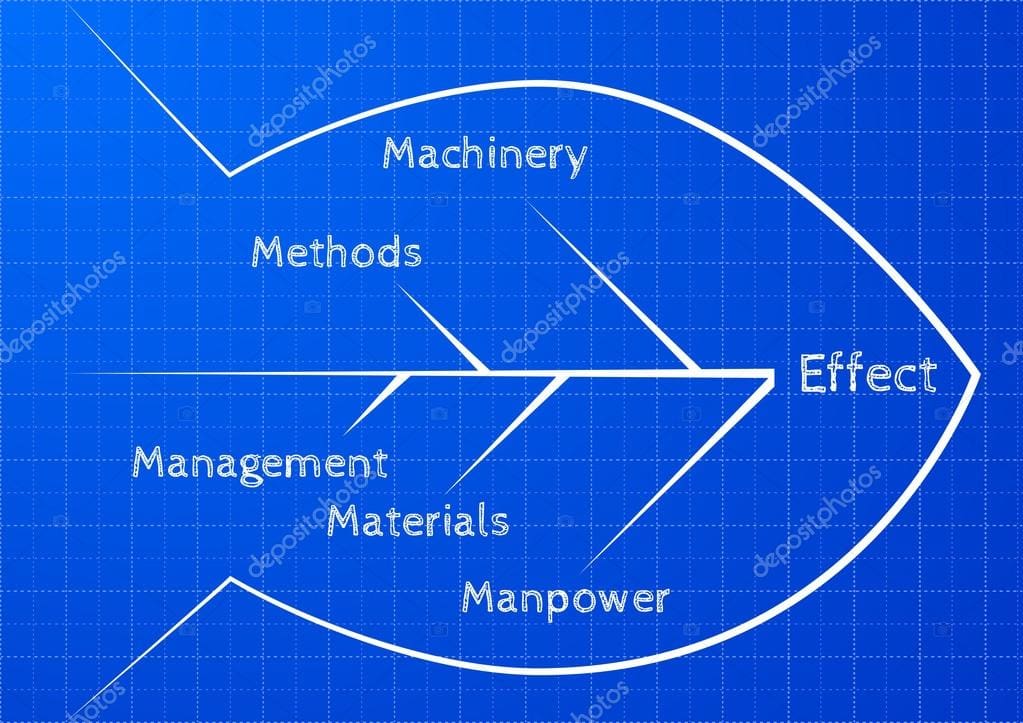

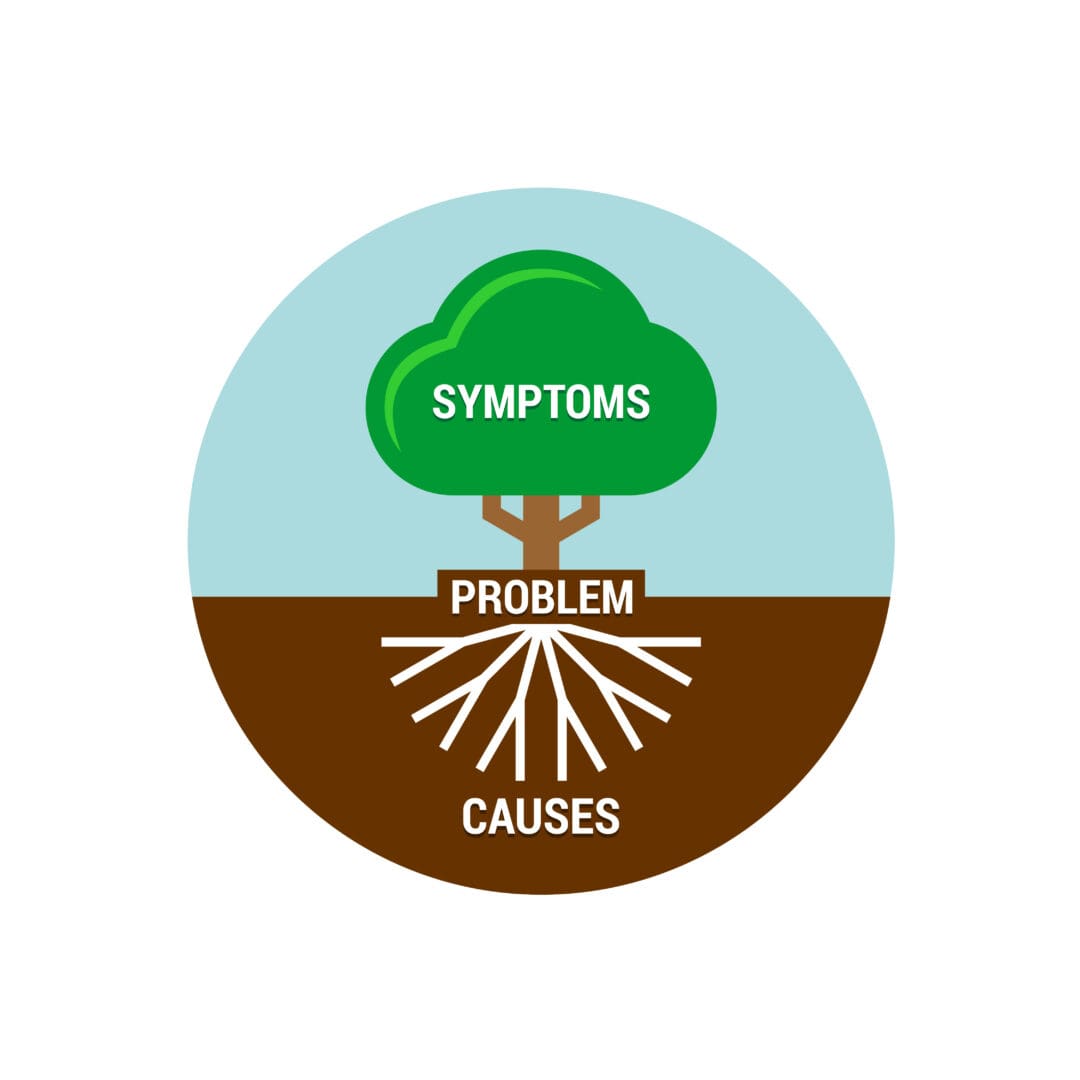

We will be employing some Lean Six Sigma tools to perform root cause analyses on the gaps we discover to help us prioritize and quantify the financial / operational impact of these issues.

This holistic view will give our team a strong idea of what are the main priorities to focus on when providing recommendations for improvement.

Implementing your Future State (Improve or Design)

When there is a clear understanding of the business, it's success criteria and its challenges, it becomes very easy to understand what the fixes should be. In many cases our group of Process Engineers and Developers will make use of today's technologies to innovate and implement new tools and solutions. Our team will:

1. Documenting the new Desired Future State that was established as changes required with process, developing new process, procedures, or re-allocation of resources, new roles, new business rules, and/or new tools and reports.

2. Implement the recommended changes

3. Pilot the changes with a small-scale deployment

4. Iron out the kinks by learning from the Pilot

5. Determining how to launch at a wider scale along with determining the control plan

Sustainment (Control or Verify)

One of the hardest things to do is to ensure adoption to anything that is 'new' even if it makes our jobs easier. We're creatures of habit. While we bound this phase in terms of the support that is provided, the commitment by our customers must be continuous. After the implementation of a new solution (whether it be a new tool, service, process, etc), our team will remain in the market for at least 3 months (depending on the scope of the project) to ensure adoption by all of the key players and stakeholders. A Control Plan is developed in the previous step and is executed in this phase. As part of the plan our team will ensure that:

1. The new processes, tools, changes are fully adopted

2. The performance of these changes is evaluated to put triggers in place on whether intervention is required to stay on track

3. The discipline of reporting the value obtained from these changes is adequately implemented (The right reports with the right data, the right cadence, and the right visibility).

Lean Six Sigma Tools We Use

Thankfully Lean Six Sigma techniques and methodologies have paved the way to helping organizations become operationally efficient. It's just a matter of leveraging these proven techniques, tools and methodologies. Our trained Master Black Belts who have had experience particularly in the telecom industry know exactly when to use the right tools and for any given challenge. Below is a non-exhaustive list of tools, techniques and methodologies that we use.